Queen Mary University researchers have developed a self-enhanced, variable-stiffness artificial muscle that mimics natural muscle features. This breakthrough has significant implications for soft robotics and medical applications, moving towards human-machine integration.

Researchers from Queen Mary University of London published a study on July 8 in the journal Advanced Intelligent Systems, which revealed that the development of a new type of electric variable-stiffness artificial muscle with self-sensing capabilities is a major breakthrough in bionics. This technology has the potential to revolutionize soft robotics and medical practice.

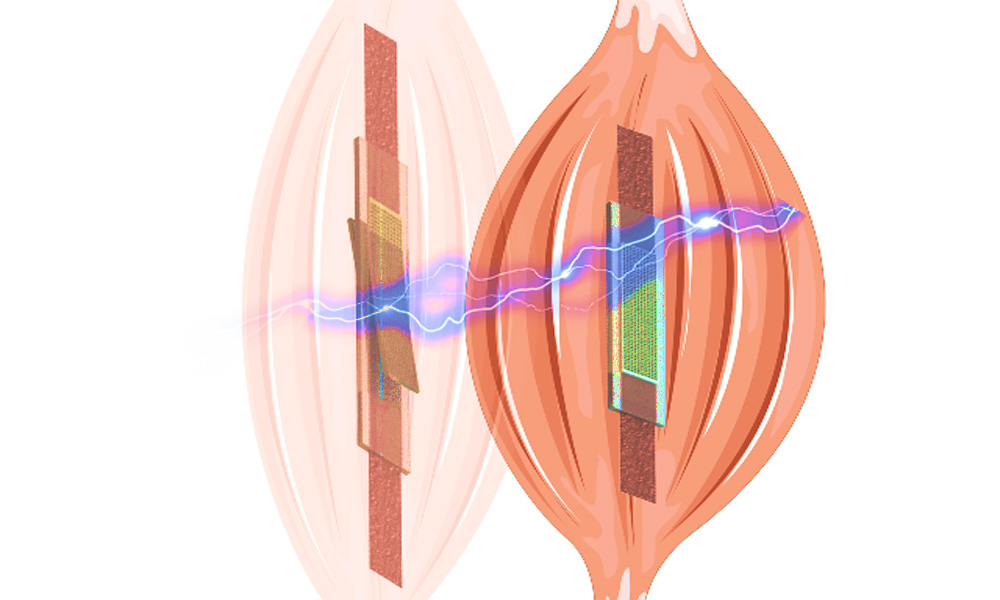

The hardening of muscle contractions is necessary for strength and speedy reactions in living beings. A team at QMUL’s School of Engineering and Materials Science has mimicked the natural transitions between soft and hard states, resulting in an artificial muscle that can sense both soft and hard forces and deformations.

The researchers have developed a revolutionary artificial muscle that is both flexible and stretchable, much like natural muscle, making it a perfect fit for integration into complex soft robotic systems and adaptable to various geometric shapes. With the ability to withstand over 200% stretch along the length direction, this actuator with a striped structure demonstrates exceptional durability.

Dr. Ketao Zhang, a Lecturer at Queen Mary and the lead researcher, emphasizes the significance of variable stiffness technology in artificial muscle-like actuators. He believes that empowering robots with self-sensing capabilities is a crucial step towards real bionic intelligence.

The artificial muscle can be subjected to a range of voltages and can adjust its stiffness rapidly, resulting in a continuous modulation process that alters its stiffness more than 30 times. This technology is not only voltage-driven but also provides a significant improvement in response speed compared to other types of artificial muscles. It can also monitor its deformation through resistance changes, which eliminates the need for additional sensor arrangements and reduces costs.

The production of this self-sensing artificial muscle involves a simple and reliable process where carbon nanotubes are mixed with liquid silicone using ultrasonic dispersion technology and coated uniformly with a film applicator to create the thin layered cathode. The anode is made directly using a soft metal mesh cut, and the actuation layer is sandwiched between the cathode and the anode. The layered cathode also serves as the sensing part of the artificial muscle. As the liquid materials cure, a complete self-sensing variable-stiffness artificial muscle is formed.

The technology has a wide range of applications, from soft robotics to medical devices, where its seamless integration with the human body could help people with disabilities or patients perform basic daily tasks. By integrating the self-sensing artificial muscle, wearable robotic devices can monitor a patient’s activities and adjust stiffness levels to help restore muscle function during rehabilitation training.

Despite the obstacles that still need to be overcome before these medical robots can be used in clinical settings, Dr. Zhang believes that this research is a significant step towards integrating humans and machines. He believes that this will pave the way for the future development of soft and wearable robots.

Reference: “An Electric Self-Sensing and Variable-Stiffness Artificial Muscle” by Chen Liu, James J. C. Busfield and Ketao Zhang, 8 July 2023, Advanced Intelligent Systems.